Pixargus at ICE 2017: The new generation of the Pixargus WebControl Surface system detects surface defects also in foils and technological web material with highly complex textures. It minimizes waste and guarantees that only perfectly flawless material is used in downstream processing. The system is the first to combine complete surface inspection and dimension measurement within one single sensor unit. The integrated MultiArea scanning feature opens up entirely new of optical inspection.

WebControl Surface (S) detects flaws in challenging surfaces of non-transparent or (semi-)transparent material and composite materials. It automatically adapts to the texture being scanned. The system is typically used with any kind of technological webs as, for example, used as interior lining material in vehicles.

Intelligent software masks out intact surface structure

While the system is analyzing a surface, a special algorithm identifies the natural surface structure and automatically masks out that structure. Thus WebControl S is able to also detect hidden flaws, i.e. those difficult to discern against the natural structure of the material. The system detects and classifies irregularities in synthetic or real leather structures, flaws in the weave of glass-fiber mats, orange-peel effects on dark, opaque foils, dense spots in non-woven fabric and even light streaks or scratches. As soon as the system finds a defect, it triggers an alarm and, as an optional feature, marks the affected area. An algorithm for the detection of elongated defects - for example, linear marks or weaving defects - enables conclusions to be drawn as to the existence of defective rolls in the production line.

Automatic adaptation to structure and color

The dynamically operating system automatically adapts to the surface structure and color of the material. Unlike competing inspection systems, WebControl S usually does not require any time-consuming teach-in of the surface structure. All that needs to be done is to enter the relative amplitude of the texture as a roughness parameter and the size of the smallest to be detected defect. For the management of defect classes and defect densities a tool is provided that allows to formulate simple detection and classification rules. Moreover, the operator can define by himself which and how many defects are to be tolerated within a specified area.

Virtual cameras provide MultiArea functionality

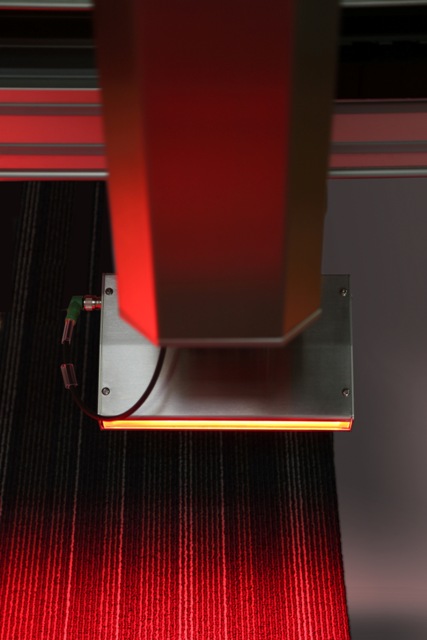

WebControl S features a modularly adjustable MultiArea scanning function – a genuine innovation in image processing technology. The new MultiArea functionality complements the physical sensor equipment by virtual cameras. This makes it possible to define as many fields of vision as desired with different parameters (e.g. defect sizes) and perform various inspection tasks at the same time. Pixargus uses its newly developed LED light line elements, which create a strong contrast on the material surface due to their extraordinary light bundling capacity. Additionally, these LED-based elements have a distinctly longer service life than conventional lights. All optical components are sealed according to IP 64. Through remote access via Ethernet and IP-based communication it is possible to make swift diagnoses of the system and, what is just as important, to remotely change and adapt the parameter settings.

New Machine Vision software makes for ease of operation

The system is controlled by means of the new Pixargus-developed Machine Vision software. HMI is via a tiltable multi-touch screen offering enhanced graphical display features. The screen works like modern tablets or smart phones: simply touch the element you want to select, move an object by dragging your finger across the screen or zoom in or out by pinching or spreading two fingers. The enhanced auto focus capability speeds up camera setting and hence the line start.

Quality data viewable at a glance

WebControl S provides the measured data and evaluations in real time and processes data relevant for the product quality in the form of a “defect map”. Intelligent Big Data analysis functions make the production chain more transparent, especially at quality-critical production stages. Repetitive defects can be prevented and the manufacturing process can be optimized in a pinpoint manner. The system can be easily integrated into corporate network structures, SAP environments and existing PDA and ERP systems, and networked with other sensors and measuring systems. It is suitable for horizontal and vertical integration into innovative Industry 4.0 applications. All components of the system can be controlled within a decentralized structure at the line or centrally via a server.

Scalable system for flexible use

WebControl S is a modular system, available for material widths between 150 and 8,000 mm. For different surface characteristics, Pixargus supplies the system with different camera resolutions ranging between 10 and 150 µm. Opaque product can be inspected on one or both sides. The system operates at material speeds of up to 800 m/min depending on the product texture. Thanks to its compact design and innovative assistance features, the system is quickly set up and ready for use as a flexible in-line system providing reliable measuring data during the start of a line and throughout an entire production campaign.

“We have taken the next step where others stop”

Summarizing the benefits for producers of web material, Dirk Broichhausen, Vice President Sales & Marketing at Pixargus, states: “So far manufacturers of surface inspection systems have concentrated on material with a uniform surface structure, such as metals, foils or paper. Working with completely new algorithms, our systems are able to also reliably detect surface defects against most irregular backgrounds. They know how to find the needle in the haystack or, in other words, we have taken the next step where others stop.” Pixargus customers use the data provided by the system not only for quality assurance in final product inspection but also for optimizing the production process and preventing defects in the first place. For example, the fact that also trends in the density of surface defects are captured in real time enables countermeasures to be taken instantly. The operators can immediately take corrective actions and sort out any defective material.