Whether it be plastic profiles for windows, cable conduits or skirting boards – in extrusion processes of high through-put rates automated inline quality control has many advantages: Flaws occurring during production can be detected much earlier and corrected in real time. This saves feed material and reduces out-of-spec products and costs. With iProfilControl (iPC), measuring technology specialist PIXARGUS is launching a smart basic series for optical quality inspection. The cost-optimized downsized models provide top inspection performance at a highly attractive price. PIXARGUS has adapted the system capacity, the range of functions and the hardware to meet exactly the requirements of the process on hand, in other words: maximum efficiency by purpose-tailored equipment. Starting with a 4-camera model, the system can be scaled up to 6 or 8 cameras, as required, to meet the needs of every process situation.

iPC Surface (S): 100% surface inspection

iPC S is our most compact solution for complete, 100% inspection of all visible surfaces. Special Light-Edge elements developed by PIXARGUS ensure that the measuring field is extremely homogeneously lit, allowing the camera sensors to immediately capture and process even those irregularities and defects that were not visible or only difficult to detect in the past – pinholes, for example, or pores, scratches, cracks and grooves. Also profiles with edges and various different angles can be inspected 100% thanks to the possibility of using up to 8 cameras.

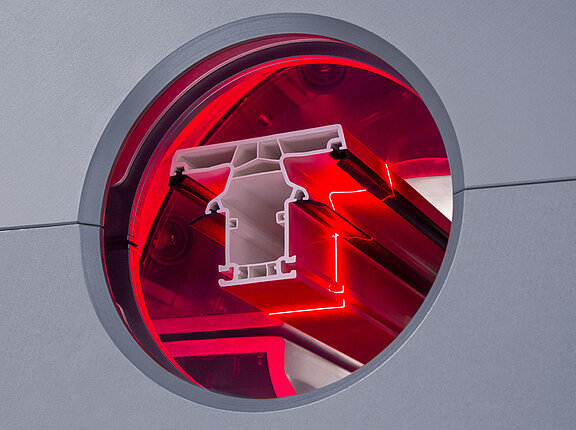

iPC Dimension (DX): 360° geometry measurement

Whether it be widths, gaps, angles, radii, shapes – iPC DX detects even most minute deviations from the target contour thanks to its eight laser line sensors watching closely the dimensions of the inspected product. This impressively high number of optical sensors is needed, in particular, to capture the complex geometry of the clamping grooves, which can only be measured with sufficient accuracy with cameras arranged at different angles and positions. The models of the basic series come with a number of features known from their big brother, ProfilControl 7. The hinged arrangement of the sensor head securely prevents the measuring field from being affected by parasitic light effects.

iPC DualVision (DV): The multi-talent

iPC DV combines 100% surface inspection and 360° dimension measurement within one single sensor unit. The integrated MultiArea scanning feature opens up entirely new possibilities for optical inspection. The smart MultiArea functionality complements the physical sensor equipment by virtual cameras. This makes it possible to define - by defect sizes and other parameters - as many fields of vision as desired for each camera and perform various inspection tasks at the same time. The measuring modules are integrated within one sensor head and switchable separately or in parallel. Operators do not need to invest in a second inspection unit because our highly compact system is a multi-talent – with clear cost advantages.

Software based on the proven PC7 inspection technology

When it comes to software, PIXARGUS never ever accepts any compromises in terms of performance, efficiency or reliability. The new iPC series measures with a repeat accuracy of 0.01% of the field of vision (FOV) – this is an extremely good value, also in comparison with competitor systems. Any profile surface and geometry, no matter how complex, is scanned and inspected within seconds. The system signals extremely small irregularities long before the out-of-spec tolerance limit has been reached. This enables the production process to be controlled in a most efficient way.

Space-saving desk-top systems – ready to run!

The iPC models come as desk-top systems of compact, cost-optimized design. The computing unit is integrated within the system. As no electrical cabinet and other accessories are needed, the system requires very little space in the line, making it extremely easy for the operator to integrate the system into the production line. Rated at IP54 or higher, the casing – of proven stainless steel design - and the wiring are laid out to cope with the high mechanical stresses and other influences encountered in severe industrial environments. All three standard variants (FOV diameters of 90/170/250mm) come with a hinged sensor head.

Networkable and upgradable

Our entry-level series does not include a monitor. Instead, the systems can be touch-operated via a tablet, notebook or even a network-connected PC. iPC comes with interfaces for TCP/IP and digital I/O signals as standard. Additional interfaces such as OPC UA, Wifi and PLC etc. are available as options. The basic models can be upgraded and adapted to specific series production parameters or other requirements, as required, and to higher process speeds.

Click here for more product information about iProfilControl.