Whether it be plastics profiles for windows, cable conduits or skirting boards – in extrusion processes, optical inline quality inspection has many advantages. With the new compact inspection systems from PIXARGUS, flaws are detected much earlier than before and can therefore be corrected in real time. This tangibly reduces out-of-spec production. Reduced to the max, the new cost-optimized downsized models provide maximum inspection performance at a highly attractive price.

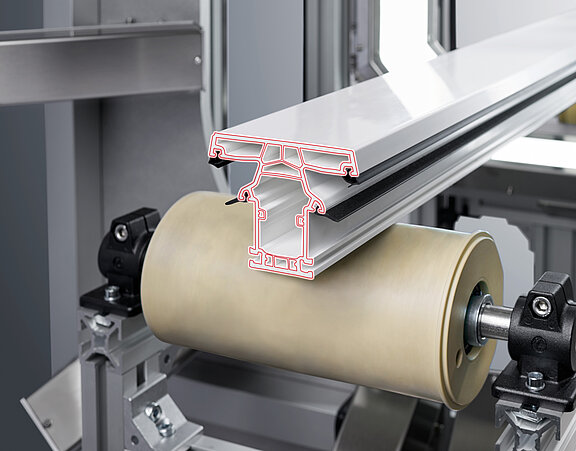

iProfilControl: The rationally-priced basic systems series for complete 360° inspection of profiles

360° dimension measurements or 100% surface inspection - or both, as combined within our All-in-One solution: our compact iProfilControl entry-level gauges come with proven inspection technology known from our ProfilControl 7 series. Starting with a 4-camera model, the system can be scaled up to 6 or 8 cameras, as required, to meet every process requirement.

iPC Surface (iPC S) assures complete, 100% inspection of all visible surfaces. It is able to detect abnormalities and defects that were extremely difficult to detect in the past - pinholes, for example, or pores, scratches, cracks and grooves. Also profiles with edges and various different angles can be inspected 100% thanks to the possibility of using up to 8 cameras.

iPC Dimension (iPC DX) is the expert gauge for widths, distances, angles and radii, able to detect ultra-small deviations from the target contour thanks to its eight laser line sensors “watching closely” the dimensions of the inspected product, including the complex geometry of the clamping grooves.

iPC DualVision (iPC DV) - our All-in-One solution - combines 100% surface inspection and 360° dimension measurement within one system. The integrated MultiArea scanning feature opens up entirely new possibilities for optical inspection. For each camera, as many fields of vision as desired can be defined (by defect sizes and other parameters), allowing various inspection tasks to be performed at the same time. The inspection modules are integrated within one sensor head and switchable separately or in parallel. Investment in a second inspection unit is superfluous because our highly compact system is a multi-talent – with clear cost advantages.

The cost-optimized entry-level models of our iPC Basic series are virtually immediately ready to go in every production environment. They are available as compact desk-top systems with integrated computing unit.

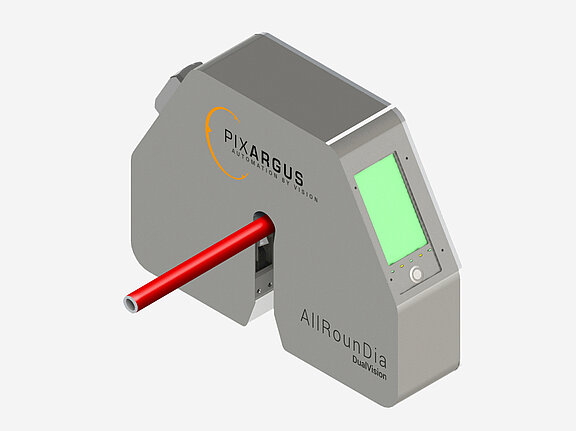

Replacing the lump detector: AllRounDia DualVision – The first genuinely cost-efficient solution for complete 360° inspection of rounds

AllRounDia DualVision (AllRounDia DV) is the first affordably priced system that measures both the surfaces and contours of tubing, tubes and cables - gaplessly, continuously and around the complete circumference of the products – with one single sensor head. A real novelty! The hardware and software of PIXARGUS’ highly successful ProfilControl 7 technology have been optimized and adapted to the measurement of product of simple, round geometries.

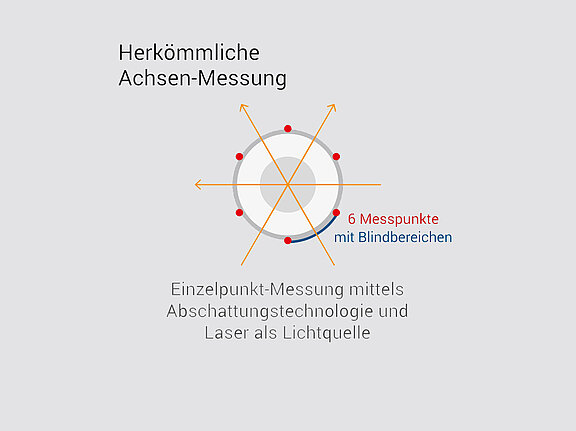

AllRounDia DV is the first ever gauge able to deliver gapless 360° measurement of round and oval contours. PIXARGUS achieves this by employing a camera-based, laser-triangulation method. While conventional axis-based measurements using the shadowing method cover only six single points, the optical sensors of AllRounDia DV capture 8 million pixels! In this way, not only the larger defects (nodes), but all defects of any size are captured 100%. What is more, the two-in-one system simultaneously inspects the surface for defects. The specially developed lighting concept ensures that the field of vision and the measuring field are perfectly homogeneously lit. Precisely for this reason, even difficult to detect irregularities and flaws in the material, such as fissures, inclusions, flecks and other high-contrast defects from a size of only 0.1 mm, are reliably captured.

AllRounDia DV’s extremely compact design enables it to be ready to run in the production line with virtually no effort at all. It is available as a stand-alone unit or mounted on a stand base.

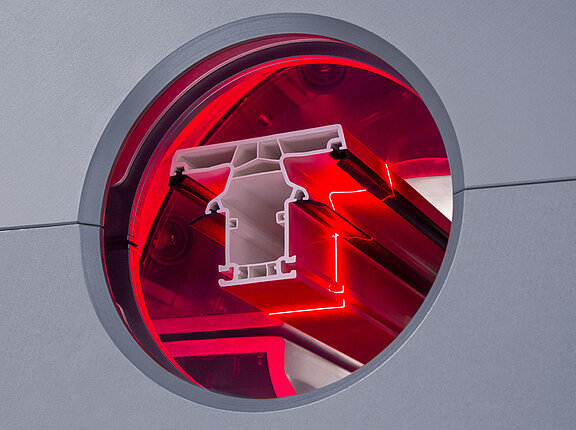

A milestone in inner geometry measurement: ProfilControl 7 ICSM not only inspects the inner contour of cut plastics profiles in an inline process, but also measures the rate of recycled material

The new Pixargus ProfilControl 7 DX ICSM (PC7 ICSM) is the first inline gauge measuring the inner cross section and the clamping sections of cut profiles immediately after the cutting device in extrusion lines. The gauge can handle profiles made of plastics, rubber or metal. Flaws occurring during production can be detected much earlier and corrected in real time. But the system can do much more: PC7 ICSM also measures and controls the rates of recycled material used in extrusion processes, making it possible to increase the use of recycled material to the maximum possible limit.

The new inline system replaces conventional offline measurements using tabletop projectors. It makes time-consuming and costly manual preparation of sample cross-sections redundant, as the ICSM module inspects the cut profiles immediately after the cutting process. This assures 100% inspection of each profile of a batch at every cut.

PC7 ICSM combines ideally with the two-in-one system ProfilControl 7 DualVision (PC7 DV). This top-selling gauge assures maximum inspection performance by inspecting the surface and measuring the outside contour in a single process. It is available as an inline operating system or as a stand-alone, offline measuring station.

Perfectly networked: iProfilControl, AllRounDia DV and ProfilControl 7 ICSM

iProfilControl, AllRounDia DV and ProfilControl 7 ICSM come with all common interface ports as standard. Their connectivity can be further expanded by numerous additional options, all of which make the integration of the gauges into corporate network structures, SAP environments and existing PDA and ERP systems very easy. All our inspection systems can be networked with additional sensors and measuring systems, and integrated – horizontally and vertically – via an OPC UA interface, for example, into innovative Industry 4.0 applications.

Visit PIXARGUS at the K Trade Fair: Hall 10, booth G42