In highly specialized industries, quality requirements have become increasingly complex and sophisticated. For example, the automotive industry banks on innovative, technologically demanding composite materials; medical grade tubing has to comply with highest safety standards, and so forth. The growing competitive pressure has lead more and more businesses to look for sustainable ways to optimize their processes in terms of quality, time and costs. Therefore, more and more manufacturers have been demanding zero-defect quality from their suppliers because in an extreme situation a human’s life may depend on the quality of their products.

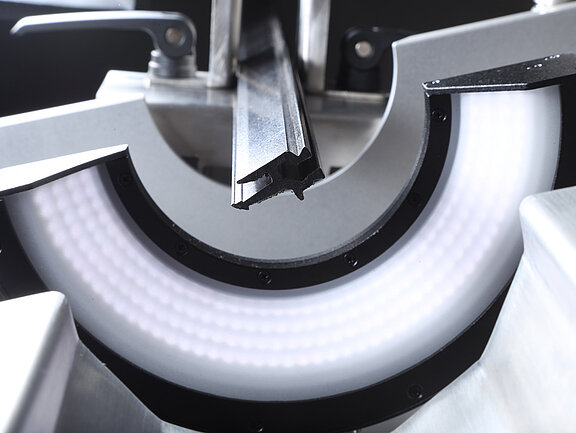

With the latest generation of the ProfilControl 7 inspection systems, measuring technology specialist PIXARGUS takes industrial-scale image processing to the next level, setting new standards in the quality control of extruded products. The turnkey ProfilControl 7 Surface inspection system, for example, combines both surface inspection and dimension measurement within one compact, modularly scalable system. For the first time, both control modules have been integrated into one common sensor head, allowing them to be switched separately or in parallel. Up to eight hybrid-power multi-camera sensors keep a close eye on the quality of extrusion products of simple to high complexity. As all measured data come together in one and the same sensor unit, correlating the corresponding dimensional and surface information becomes much easier. The new solution is also extremely cost-efficient, as there is no need to invest in a separate dimension measuring system.

Learn more about the 7th generation of ProfilControl inspection systems...