Reduced to the max! The cost-optimized downsized models for profile inspection of geometries and surfaces provide maximum inspection performance at a highly attractive price.

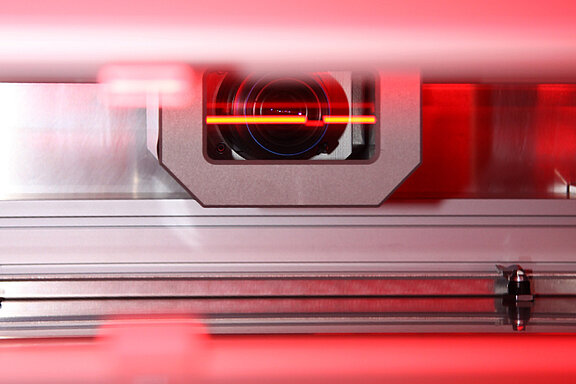

iProfilControl is the economical answer to the 360° all-round inspection of all types of profiles: whether simple or complex, made of plastic, rubber or metal - these new, scalable basic systems inspect geometries and/or surfaces with proven inspection technology - during ongoing production, in real time and 100 %.

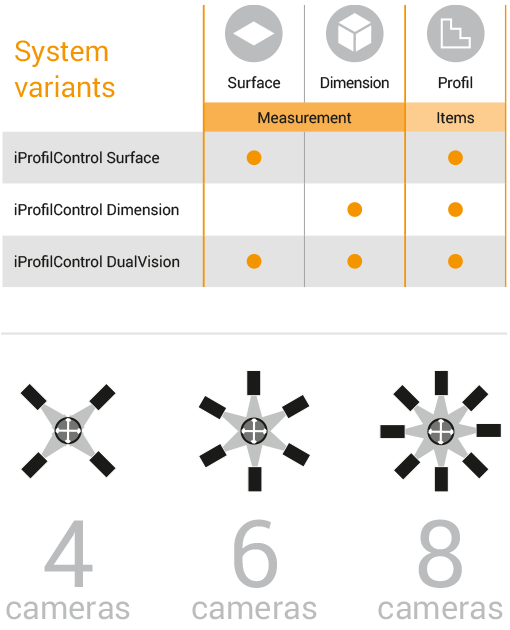

What makes the difference? PIXARGUS has adapted system capacity, the range of functions and the hardware to achieve maximum efficiency with minimized equipment. Starting with a 4-camera model, the system can be scaled up to 6 or 8 cameras, as required, to meet the needs of every process situation.

While using the same proven inspection technology as its big brother, ProfilControl 7, the systems of the basic series are much smaller in size. Thus, they can be integrated into production lines even more easily.

Available in three standard versions with opening diameters of 90 mm, 170 mm and 250 mm.

DDM Module (DefectDensityManagement)

Checks the out-of-spec rate according to rules defined based on defect density and defect size.

Optical inline inspection systems have reached a high standard in detecting and classifying surface defects on profiles. However, the contextual evaluation of defects, which includes establishing logical relationships between defect criteria, has so far remained in the grey area.

In numerous specifications, especially those set up by automotive producers, the “ship or block” decision depends on OR-operations. A customer may reject a profile, for example, if over a specified length of the product there is one severe defect or one medium defect plus several small defects.

The Defect Density Management solution, however, weights every single surface defect and sums up the obtained values over a specified length of the product. The inspection system sends out a signal as soon as the value exceeds a defined threshold. The signal can be used to mark out-of-spec sections of profiles or control downstream cutting and sorting equipment.

Drill Hole Control

Measures distances, form and diameter of drill holes.

The Drill Hole Control module checks as early as during the production process whether all venting and drill holes have been made and whether they are all in the right position. The system triggers an alarm as soon as it detects that a drill hole is missing or does not have the correct diameter or form, or that the spacing between the holes is not as it should be.

Especially for automated assembling processes, this type of inspection is paramount as it ensures that, for example, door seals can be installed quickly and reliably. In the past, checking the drill hole positions was a very complicated procedure prone to errors because the high production speeds make it impossible to take a manual measurement of each spacing. As a consequence, manual checks were only made on a random basis. Now, the new module makes it possible for the first time to check the entire profile in an inline process.

Flock Inspection

Detects flocking flaws, such as missing or clumped flocking material, longitudinal grooves and other defect types.

Pixargus developed the module for optical inline inspection of door and window seals as used in the automotive industry. These sealing profiles have to comply with extremely exacting surface quality demands.

The flocking material must be applied highly uniformly in order for the profiles to reliably fulfill their sealing function. As in the vehicles the seals are partly visible, imperfect appearance of the surface may be reason for rejects.

The direct feedback of ProfilControl data into the process control system makes it possible to instantly correct the flocking process, preventing that any poor flocking may continue along the profile.

This ensures that only perfect material is shipped to the customers.

Groove Detection

Triggers an alarm when individual flaws turn out to be continuous longitudinal grooves.

Saw Control

Cuts your product to the correct length and cuts out defects with minimal waste.

With its Saw Control module, Pixargus makes cutting-to-length an integrated part of quality control in profile production.

The Saw Control software performs two basic functions. On the one hand, it sets the cutting intervals for the shear. If set at, let’s say, one meter, profiles graded as

defect-free by the quality control system will be continuously cut to this length and discharged from the conveyor belt as ready-to-pack products.

However, in the event that ProfilControl 7 has detected a flaw in the product, Saw Control instantly causes the shear to make an extra cut in real time to remove just the out-of-spec part from the profile.

This minimizes waste and saves time. Thanks to the Saw Control module, out-of spec portions of profiles can be sorted out much faster because the operators immediately recognize them as a short length comes along.