It’s time to think in new categories: growing networking of data, flexible production plants, many different variants of a product or great quantities ... We take the new requirements and dynamics of industrial production as a chance. Therefore we have developed a range of entirely new modular, scalable and form-fit concepts for out-of-the-box or tailor-made industrial plants.

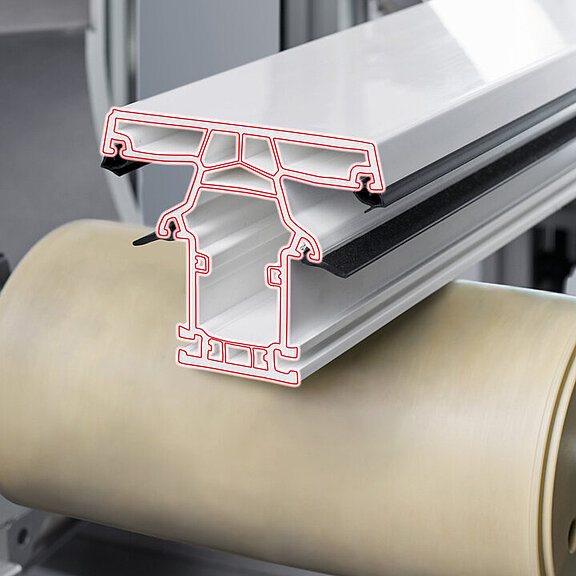

Classic Solution

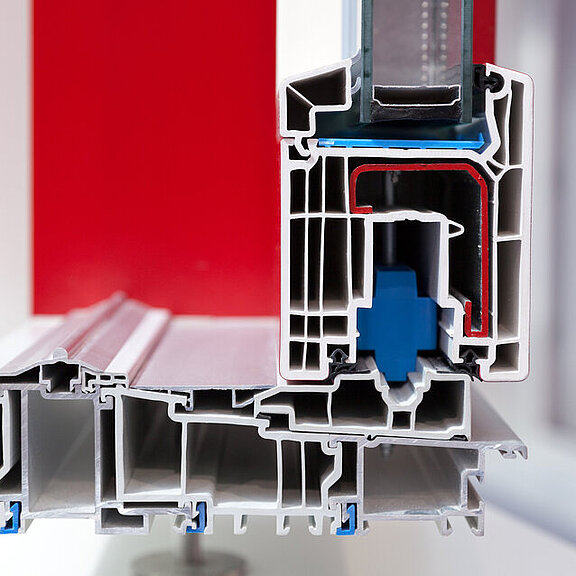

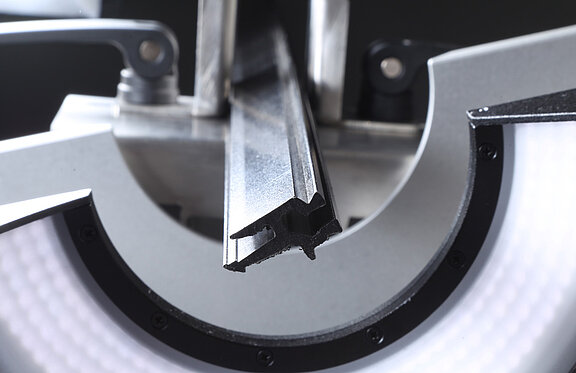

Our Classic Line of systems sets standards! Featuring state-of-the-art sensor equipment and latest lighting technology, these compact and mobile systems provide everything you need for an automated quality inspection process. The extremely space-saving design of the units and the sensor heads that can be conveniently opened make our CLASSIC SOLUTION models extremely easy to move into or out of the extrusion line during running production or to be shared between various lines.

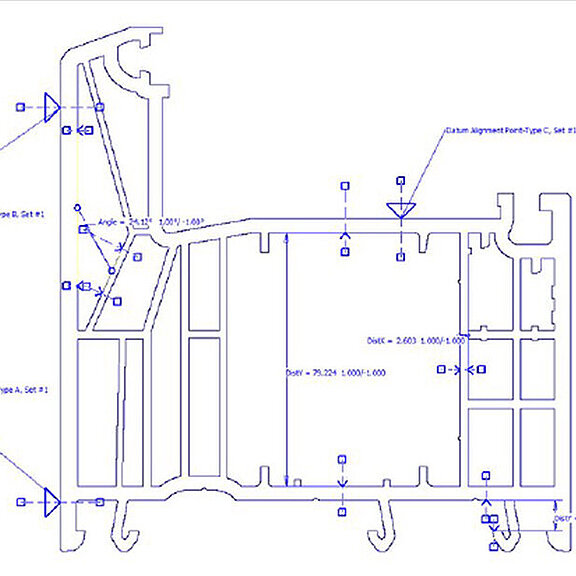

Factory Solution

Are your production lines of complex design and do they require a customized solution? Do you produce in series, in parallel, with value-adding systems? No problem. With our modular FACTORY SOLUTION line, we are able to perfectly cater to your specific needs. For example, while all the camera and sensor equipment are installed within the line, the processing unit could be placed safely in the server room - a solution for maximum security of investment. Or do you work with an Industry 4.0-ready decentralized network of sensors and a CPU? No problem either …Together, we will find the most suitable solution for your application – in terms of both logistics and economy.

Basic Solution

You are still at the beginning of your investments in automatic quality inspection equipment? Or maybe you only need a smaller solution for less dynamic production or inspection processes? Then you may want to go for the down-sized systems of our BASIC SOLUTIONS series. While featuring our proven sensor equipment, the systems come in a design and with a capacity efficiently adapted to the performance range required, in other words: reduced to the max! In terms of both ergonomics and economic efficiency. Your additional benefit : the systems can be controlled and operated by mobile devices, e.g. via a tablet. And, needless to say, everything is of quality “made in Germany”.

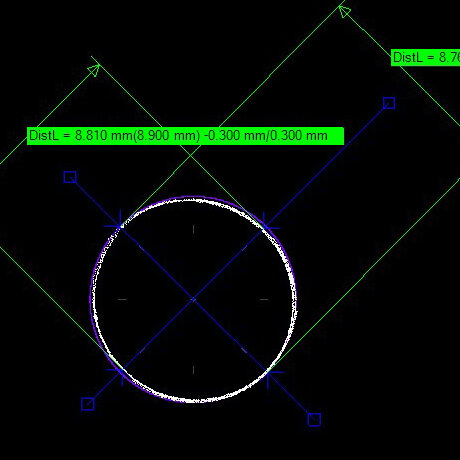

Engineered Solution

Are you gearing up for new projects? Having to solve extraordinary measuring tasks? Taking a future-oriented approach to innovations? Our ENGINEERED SOLUTIONS are high-end technological solutions specifically designed to perform all measuring and inspection tasks to guarantee 100% quality control – in a separate, fully automatic measuring station. In designing these solutions, we build on decades of experience, knowhow from countless most different applications and in-depth engineering proficiency.

![[Translate to English:] IMG_1159_bearb_produktkachel_stoerer-EN_neu.jpg](/fileadmin/_processed_/1/d/csm_IMG_1159_bearb_produktkachel_stoerer-EN_neu_1ff9940461.jpg)