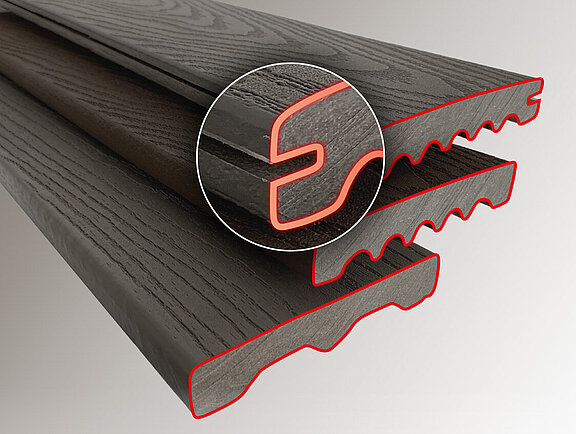

Looking for decking that leaves nothing to be desired? Decking that is designed to last, be resistant to fading, has a natural look, and is safe for children and pets, as it resists splintering and is non-slippery? You can get all this from composite decking. Wood-plastic composite decks are the sustainable alternative to traditional wood decks made from exotic hardwoods.

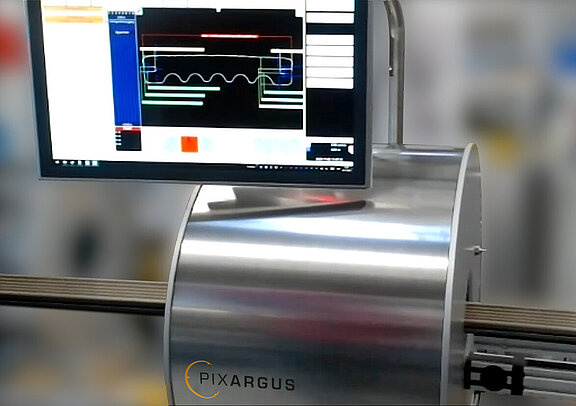

Thorough quality inspection is also essential for these innovative WPC products. A new inline inspection system from PIXARGUS – ProfilControl 7 DX WoodPlasticComposites – is now available to ensure that all of the deck boards leaving a manufacturing line are of perfect shape. The system is of compact design and based on PIXARGUS’ proven and successful PC7 inspection technology. One such system is now successfully in use at a leading decking and cladding boards manufacturer in the USA.

OPC-UA interface is the pathway to fully automatic manufacturing

This renowned US deck board producer has recently made great strides in automating its production processes. In 2022, all process steps, machines and equipment were networked and linked with the higher-level control systems. The company now uses the new smart inspection system from German measuring specialists PIXARGUS to make quality control of its extruded deck boards a fully automatic process.

The camera-based digital inline inspection system ProfilControl 7 DX WPC from PIXARGUS comes with an OPC-UA interface that allows it to smoothly and seamlessly integrate with the manufacturer’s process chain and communicate with the various control units and downstream processes in real time.

Automatic product grading and stacking

In addition to providing 100% inspection of the deck boards in a continuous process, the measuring system’s smart software is also instrumental in grading the products fully automatically. Boards graded as defect-free are automatically stacked ready for dispatch.

Automated product switching

The link between the PIXARGUS system and the manufacturer’s higher-level control systems also enables automatic switching from one product variant to another. Upon a signal received from the line control system, ProfilControl 7 DX WPC automatically adjusts to the inspection parameters of the new product – during running production.

A first in quality control: 100% inspection even of critical features such as deep grooves

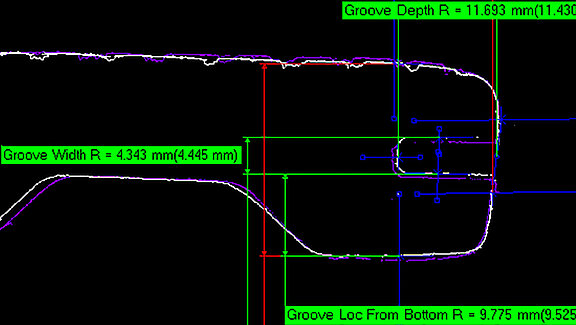

After the deck boards have been cut to length, the eight high-resolution cameras of the ProfilControl 7 DX WPC system capture the contours of the boards in an inline process, checking all radii, angles, distances, lengths, heights and widths. For the use case at the US deck board manufacturer, PIXARGUS has positioned the cameras in such a way that also the entire grooved edges of the deck boards can be measured. These grooves will later accommodate the fasteners to install the decking.

While the standard measuring systems the US customer had used in the past were only able to measure either the height or the depth of the groove, ProfilControl 7 DX WPC uses a specially adapted sensor head to measure both parameters of the highly challenging groove geometry simultaneously with just one measurement (IMG 4).

Turnkey solution designed to cope with the most challenging production conditions

ProfilControl 7 DX WPC is supplied calibrated ex works. The process reliability and measuring accuracy are in compliance with MSA type-1 and type-3 studies. This means the system fulfills even the most exacting internal QM requirements. It is designed for up to 250 mm wide products and stable operation under the most challenging production environments. The sensor unit is protected by an enclosure. This makes the measuring equipment highly resilient to contamination. The new PIXARGUS system has already proved highly successful at the US customer’s operations.