Compact. High performing. Reduced to the max.

With iProfilControl, PIXARGUS offers its proven technology for surface inspection and geometry measurement in a cost-optimized series of downsized models. As specialists in measuring technology, we have adapted the system capacity, the range of functions and the hardware to the specific requirements of the process – maximizing efficiency by purpose-tailoring the equipment. Also regarding the price this series can score points.

Whether designed as an entry-level system or as a system for complex extrusion processes – iProfilControl always provides efficiency for the essential.

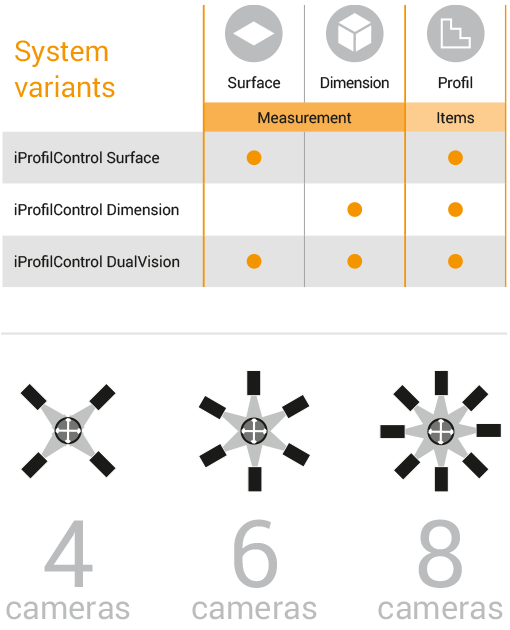

Our basic systems, iProfilControl, can be fitted with 4, 6 or 8 cameras to meet your specific process requirements.

You are still at the beginning of your investments in automatic quality inspection equipment? Then our 4-camera systems provide you with the ideal starting basis.

You are planning to upscale step by step and retrofit your system at a later stage? No problem. Our systems grow with your requirements. They can be retrofitted to 6 or even 8 cameras to cope just as reliably with the more complex inspection or measuring tasks.

Even when used at maximum system rating, the design and function of our basic systems are optimized to provide you with a distinct advantage in terms of cost efficiency.

What iProfil measures

Surface

iProfilControl Surface ensures 100 % inspection of all visible surfaces. Even profiles with edges and various different angles can be inspected 100% thanks to the possibility of using up to 8 cameras. The system detects scratches, bubbles, cracks, grooves, etc. as well as non-topographic defects such as colour deviation, markings etc.

Dimensions

iProfilControl Dimension projects a straight, extremely sharp laser light line onto the product, so that contour, distances, angles, radii, etc of any profile geometry, no matter how complex, are captured in a matter of seconds and compared with the nominal profile data in the CAD system.

![[Translate to English:] Oberflächeninspektion und Geometrievermessung von Profilen [Translate to English:] Oberflächeninspektion und Geometrievermessung von Profilen](/fileadmin/_processed_/a/5/csm_img_ipc_2_65f344f1aa.png)

![[Translate to English:] iPC: Prüft Geometrie und Oberfläche von Profilen [Translate to English:] iPC: Prüft Geometrie und Oberfläche von Profilen](/fileadmin/Bilder/Produkte/iProfilControl/img_ipc_1.png)