Optical inspection systems for quality that shows!

PIXARGUS offers an unparalleled range of turnkey inline systems for surface inspection and dimension measurement. This has made the company a world leader in automated inline quality control.

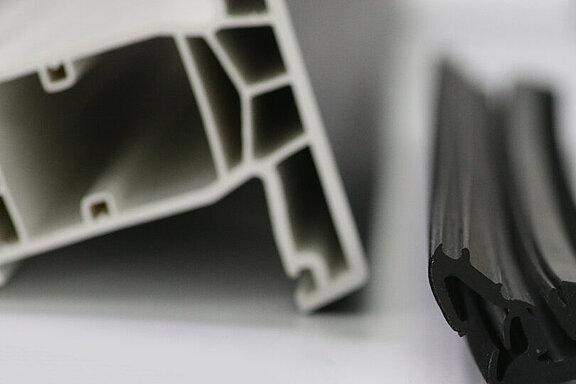

Our measuring and testing systems detect smallest defects and material deviations of extruded profiles, tubing, tubes, hoses, pipes or cables, as well as webs, film, foils, textiles, paper or fiber composites. We also check your raw materials in an automated inspection process – to ensure that your production runs smoothly from the very beginning.

Optimize your quality management with our optical defect detection systems, measure your products inline during running production or use our systems to inspect single parts.

![[Translate to English:] Rohware [Translate to English:] Prüfung von Rohware](/fileadmin/_processed_/6/8/csm_teaser_rohware_71f828c317.jpg)