With ProfilControl 7 DualVision XXL, measuring technology specialist Pixargus has launched a new inspection system which is the first cost-efficient solution providing complete 360° surface inspection and shape measurement of large coated profiles and tubes. A newly developed camera system and a new calibration technique have enabled this leap forward in inspection technology.

Whether large profiles for window construction or large-diameter tubes for energy transmission cables – the coating of large cross-sections always requires a great material input. Any damage or defect may lead to significant extra costs. For this reason alone is it essential that the product quality be continuously inspected during the production process. However, conventional systems inspecting large profiles and tubes only check the main visible surfaces of the products. In contrast, ProfilControl 7 DualVision XXL (PC7 DualVision XXL), recently launched by Pixargus, is the first system capable of providing complete inspection of all visible surfaces of large sections in a cost-efficient way. “With the new system we are now in a position to also detect any flaws in large multi-angle sections of very complex structures and edges with an unparalleled inspection accuracy,” says Jürgen Philipps, Technical Managing Director of Pixargus, which is based in Würselen, Germany. “This opens up unlimited potential for entirely new applications.” Additionally, the system is extremely versatile in terms of the material it can handle. It can inspect products made of plastics, rubber or metal.

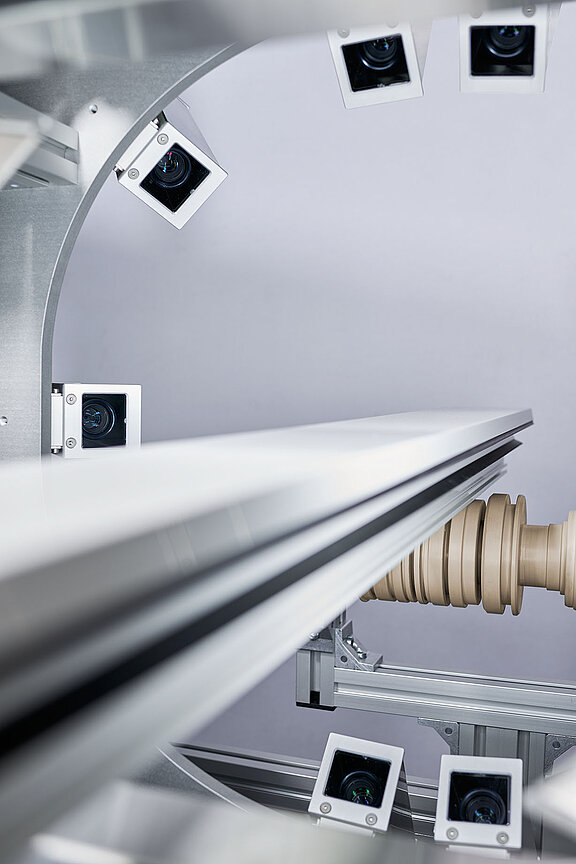

A new camera system and a new calibration process developed by Pixargus have enabled this leap forward in inspection technology. “The inspection system now calibrates electronically. Mechanical actuation has been completely dispensed with,” Philipps explains the underlying principle of the technology. “This makes the inspection process much cheaper.” As standard, the new system is designed for a maximum diameter of 260 mm. On request, it can also be customized for larger diameters.

A reference application of the new technology is the inspection of large sections at one of the world’s leading manufacturers of profiles for window frames made of PVC. What makes the inspection task extremely challenging in this case is the fact that the coating is customizable – and the variety of colors correspondingly extensive. The profiles are coated with decorative, high-gloss paints, and it is PC7 DualVision XXL’s task to inspect the coating quality. “Our system inspects more than 200 different sections of different shapes, surfaces and colors,” emphasizes Dirk Broichhausen, Director Sales and Marketing of Pixargus. The new system detects the smallest of defects in the paint, without any expensive color cameras. The inspection system also easily copes with the strong reflections of the high-gloss coating.

PC7 DualVision XXL marks any defective profiles by means of a label printer. Later on, those profiles can be easily sorted out automatically, or manually on the visual inspection desk. The new system also excels in terms of speed. “We can control process speeds of up to 30 meters per minute,” states Broichhausen. This is possible thanks to the high data processing power of the system. The inspection experts in Würselen are confident that with PC7 DualVision XXL they have provided a economically very attractive standard inspection solution for any complex-shaped large profiles.“