Corrugated tubings have become a multi-talent in machines, instruments and vehicles thanks to their extraordinary flexibility, which is rendered by their wavy structure. The special structure that gives plastic tubing this unique flexibility used to be a very rough terrain for quality inspection systems, because of the challenge of having to deal with a product surface that alternates between plane and curved structures. A reliable surface inspection system must be able to automatically differentiate between the two and inspect them - continuously – according to different specific quality parameters. All this is now possible with the groundbreaking inspection system ProfilControl 7 S CorrugatedTube (PC7 S CorrugatedTube) developed by PIXARGUS.

An innovative sensor head and new algorithms assure total defect detection

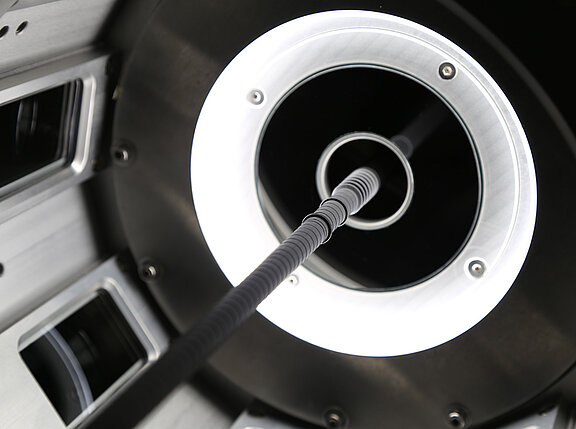

Using the successful technology of its proven PC7 S Tube inspection system, PIXARGUS has developed an entirely new sensor head for corrugated tubing. Eight high-performance cameras capture the surface structure of corrugated tubing from different angles, inspecting not only the peaks and valleys, but also the transition areas. Entirely new algorithmic processes were developed to enhance the software which is now able to detect the change from plane to wavy and vice versa by masking out specific surface structures. This makes even extremely small flaws visible. Holes, dents, blisters, nodes, scratches, fissures or poorly crimped joints will be detected with 100 percent reliability. As a result, out-of-spec production of corrugated tubing can be immediately reduced – as well as the production costs.

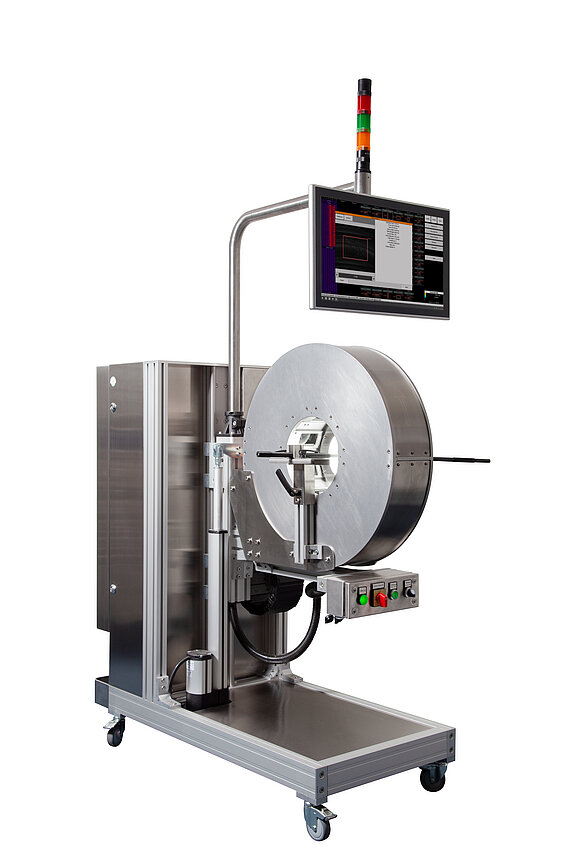

PC7 S CorrugatedTube for the inspection of corrugated tubing: Easily scalable and optimally networkable

PC7 S CorrugatedTube inspects – with highest precision - corrugated tubing of virtually any geometry, surface structures and colors. It is designed for tubing of up to 30 mm of diameter and more. The modularly scalable system can be easily integrated into Industry 4.0 environments and comes with all common interfaces, such as OPC-UA, for example.

Visit PIXARGUS at TUBE 2020: hall 6, booth J09.

Press contact:

h.freimann@~@redaktion-aix.de