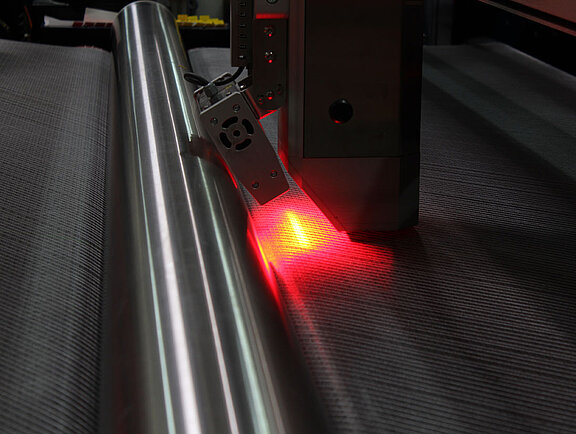

Würselen/Germany, March 2018, Pixargus at JEC WORLD: The new WebControl S inspection systems offered by Pixargus transmit light all the way through carbon fiber webs and components made of fiber reinforced composites. With its one-of-a-kind multi-camera sensor system and new lighting technology, Pixargus, a hidden champion for optical measuring systems, is opening up new capabilities of vision: Never before has it been possible to inspect CFRP webs simultaneously from various angles of view and different light casting angles. Structural deviations and flaws in the material too small to be detected by other systems will now become visible for the first time. Despite their small size, these incidents may be critical. Therefore, it is important that they are reliably detected to ensure a stable inspection process of 100 percent coverage.

Whether carbon fiber webs or organo sheet for electric car shells, carbon tape used as reinforcing material for aircraft tanks and pressure vessels or composite fabrics for light-weight construction – fiber reinforced composite materials have been gaining ground in many safety-critical areas. Therefore it is crucial to have them checked extremely thoroughly to rule out any deficiency of the material. With the new generation of WebControl S (WCS) CarbonFiber systems, inline quality control of composite fabrics is entering new spheres. “We have put an innovative technology on the market that we have successfully adapted to also meet the specific requirements of web inspection,” explains Dirk Broichhausen, Managing Director Sales & Marketing.

New multi-camera sensor technology with new capabilities of vision

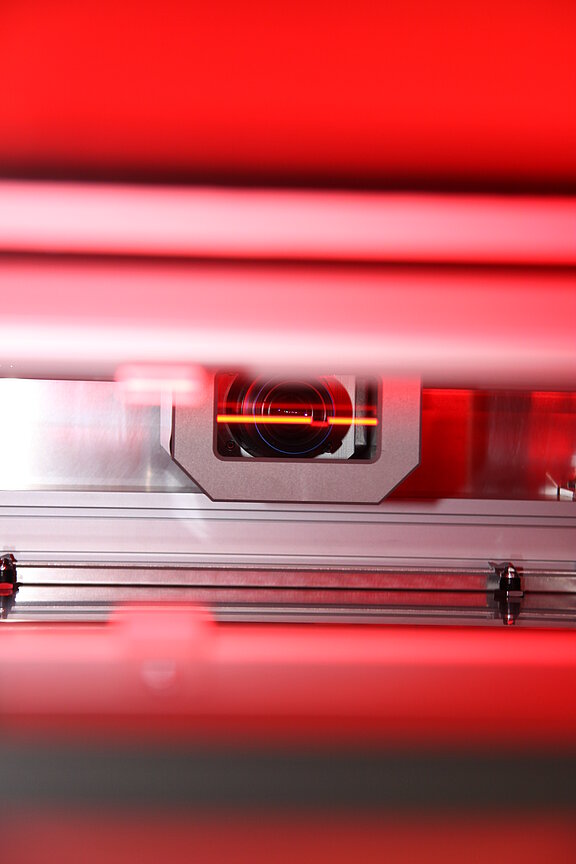

By means of a unique multi-scan technique in combination with new LED lighting elements capable of casting the light onto the composite material from different angles, WCS CarbonFiber is able to detect weaving and gap width defects or flaws in the fabric that have been undetectable so far. The high-capacity camera modules, which operate with a resolution of up to 10 µm, capture up to 1.4 billion pixels per second, depending on the specific configuration. WCS is designed to also reliably handle the strong reflectivity of the glossy material carbon.

Simultaneous inspections

A revolutionary feature of the new multi-camera sensor technology is above all the possibility of setting as many different fields of vision as desired and various light casting angles. These capabilities make it possible for the first time to perform various inspection tasks in parallel, while providing an overall quality picture of the inspected item.

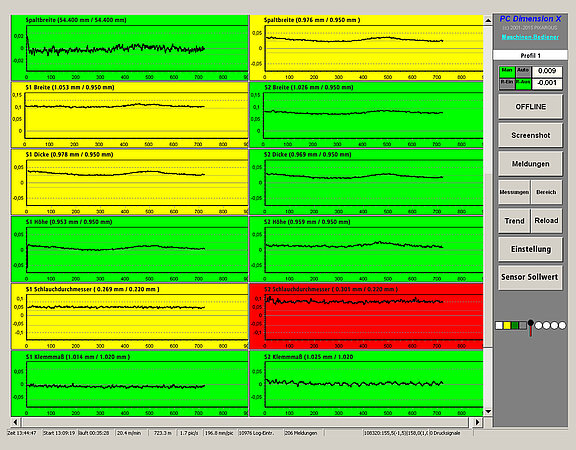

Quality data

WebControl S can be integrated into Industry 4.0 environments and is able to process measurement data from external sensors. The system performs in-depth analyses and processes the detected defects into a digital “map” for a quick review in real time and as a comprehensive presentation of the results.

Live demonstration and live inspection at JEC World

Pixargus is going to present WebControl S CarbonFiber in Paris in a live demonstration at the Pixargus stand in hall 5a. A further highlight is the live inspection of carbon tape with WebControl S CarbonFiber at the stand of the Center for Integrative Light-Weight Engineering, which is a department of the Technical University of Aachen.