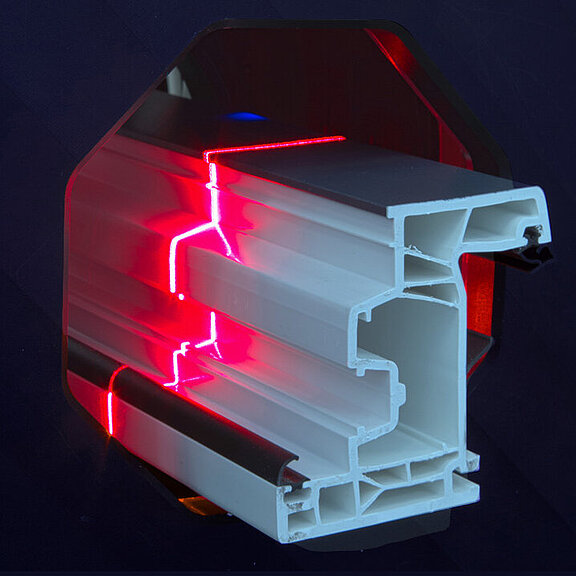

With high-precision optics and sophisticated algorithms, ProfilControl 7 DX handles with ease 360° measurements of complex-shaped profiles inline, during the extrusion process.

Up to eight high-performance, calibrated cameras detect even the most minute deviations from the nominal geometry at a very early stage in the process, thus providing for optimal process control. For more process security, efficiency and economy of production!

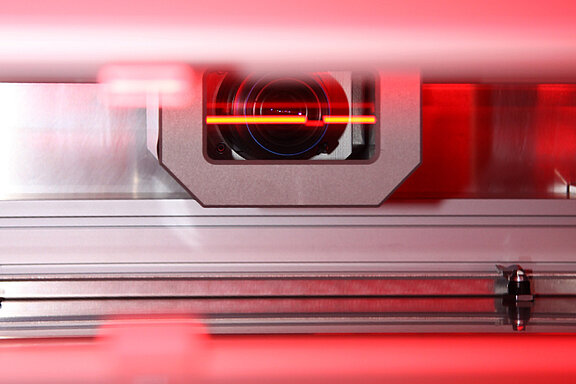

The technology? The calibration of the laser-camera system, specially developed by PIXARGUS, forms the basis for maximum precision and excellent measuring results. The system projects a straight, extremely sharp laser light line onto the product, the entire circumference of which is continuously inspected by our high-capacity cameras.

The result. Unparalleled precision. ProfilControl 7 measures spacings, angles, radii and combinations thereof with an accuracy of < 10 μm – inline, during production and in real time.

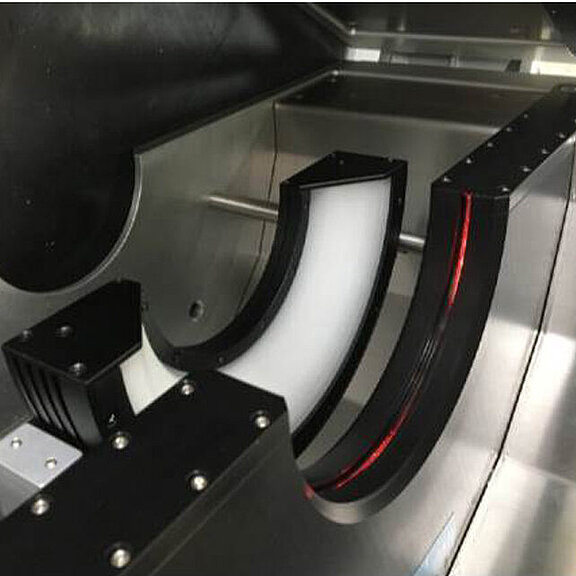

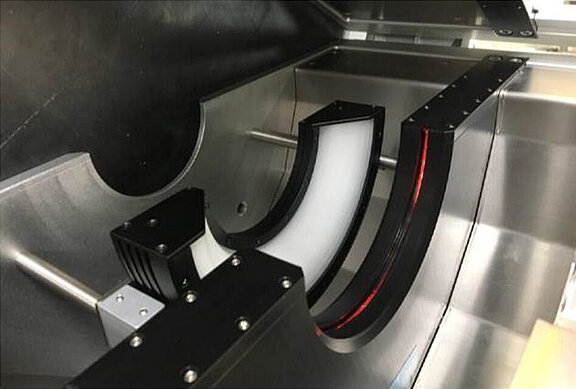

Multi Extrusion

Upgrade enabling simultaneous inspection of several extrusion strands.

Sealing profiles may also be produced by double-strand extrusion. In this case, the profiles are extruded symmetrically back to back.

To be able to measure the strands separately from each other, Pixargus has developed a special software module and added a dedicated frequency generator to its ProfilControl 7 system. The Multi Extrusion module inspects the geometry and surface of both extruded strands, while the frequency generator measures the speed and provides the optical sensors with data to adjust the image processing rate to the line speed.

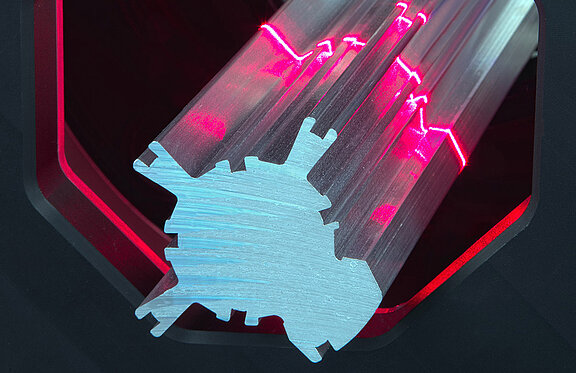

Saw Control

Cuts your product to the correct length and cuts out defects with minimal waste.

With its Saw Control module, Pixargus makes cutting-to-length an integrated part of quality control in profile production.

The Saw Control software performs two basic functions. On the one hand, it sets the cutting intervals for the shear. If set at, let’s say, one meter, profiles graded as

defect-free by the quality control system will be continuously cut to this length and discharged from the conveyor belt as ready-to-pack products.

However, in the event that ProfilControl 7 has detected a flaw in the product, Saw Control instantly causes the shear to make an extra cut in real time to remove just the out-of-spec part from the profile.

This minimizes waste and saves time. Thanks to the Saw Control module, out-of spec portions of profiles can be sorted out much faster because the operators immediately recognize them as a short length comes along.