Optical single-piece inspection of cut-to-length or die-cut micro tubing and other small items made of plastics, rubber or metal – performed by a stand-alone, fully automatic inspection unit.

Surface and edge inspection in the inclined freefall mode at a rate of up to 1,000 pieces per min. Any faulty parts with grooves, scratches, dents etc. - or inaccurately cut edges - are sorted out, ensuring that only products 100% checked and perfectly flawless are shipped to the customer.

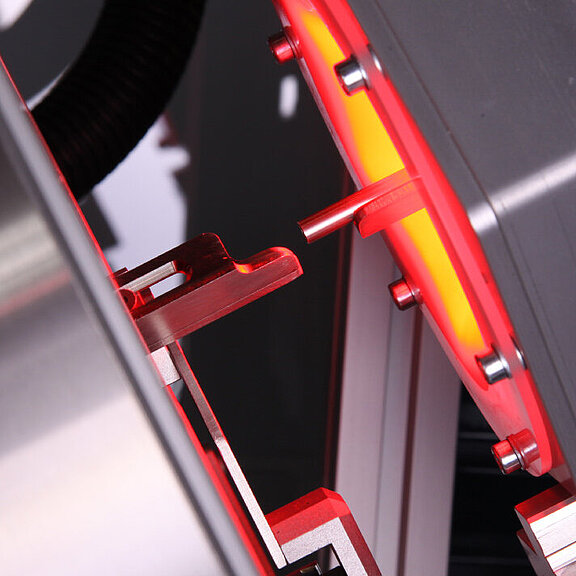

To ensure that the tubes are checked around their complete circumference from several angles all at the same time, the feeding system is provided with a gap. While the tubes are flying through this gap, their surfaces can be captured by the cameras from all directions.

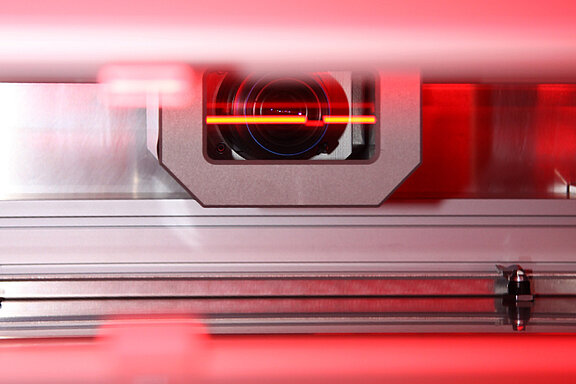

As soon as the system has detected a defect on the surface or at one of the cut edges, the system displays the defect graphically and sends a signal to the grading system. The ProfilControl 7 Inspection Automat operates so fast that any defective tubing can be removed just a few centimeters behind the measuring head. This makes the system extremely space-saving.

ProfilControl 7 Inspection Automat has been designed to even inspect mirror-finished tubes of diameters between 5 and 20 mm and lengths between 40 and 100 mm.