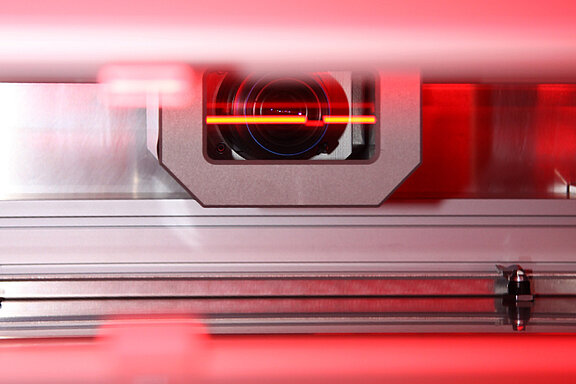

Inspection of medical tubing, pipes and cables to clean-room specifications with ultimate precision and reliability.

Using specialist multi-camera sensors, ProfilControl 7 S MedicTube inspects ultra-thin tubes down to 0.5 mm in diameter. It detects flaws such as holes, cracks, inclusions and other inhomogeneities in the tube material as early as during the production process, making productio significantly safer and more efficient.

Whether ultra-thin capillary tubing, shape-retaining tracheal and endotracheal tubes, clean-room approved cables, micro-tubing or cannulas … for these highly sensitive products, our inspection technology provides quality control of the highest level to clean-room standard.

And what’s more, the integrated pattern detection feature even identifies structures inside the tubing material, such as spirals embedded in semi-transparent, shape-retaining suction hoses. The system checks the shape of the spirals and triggers an alarm as soon as it identifies deviations.

ProfilControl 7 S MedicTube – Technology that serves the people.

DDM Module (DefectDensityManagement)

Checks the out-of-spec rate according to rules defined based on defect density and defect size.

Optical inline inspection systems have reached a high standard in detecting and classifying surface defects on profiles. However, the contextual evaluation of defects, which includes establishing logical relationships between defect criteria, has so far remained in the grey area.

In numerous specifications, especially those set up by automotive producers, the “ship or block” decision depends on OR-operations. A customer may reject a profile, for example, if over a specified length of the product there is one severe defect or one medium defect plus several small defects.

The Defect Density Management solution, however, weights every single surface defect and sums up the obtained values over a specified length of the product. The inspection system sends out a signal as soon as the value exceeds a defined threshold. The signal can be used to mark out-of-spec sections of profiles or control downstream cutting and sorting equipment.

Saw Control

Cuts your product to the correct length and cuts out defects with minimal waste.

With its Saw Control module, Pixargus makes cutting-to-length an integrated part of quality control in profile production.

The Saw Control software performs two basic functions. On the one hand, it sets the cutting intervals for the shear. If set at, let’s say, one meter, profiles graded as

defect-free by the quality control system will be continuously cut to this length and discharged from the conveyor belt as ready-to-pack products.

However, in the event that ProfilControl 7 has detected a flaw in the product, Saw Control instantly causes the shear to make an extra cut in real time to remove just the out-of-spec part from the profile.

This minimizes waste and saves time. Thanks to the Saw Control module, out-of spec portions of profiles can be sorted out much faster because the operators immediately recognize them as a short length comes along.