Reliable quality control starts as early as in the compounding stage!

ProfilControl 7 Roughness analyzes the particle size distribution in compounds ahead of the extrusion process. This ensures that only high-quality compounds will be processed. In addition to this, the generated quality data can be used to make incoming goods control more reliable and more objective.

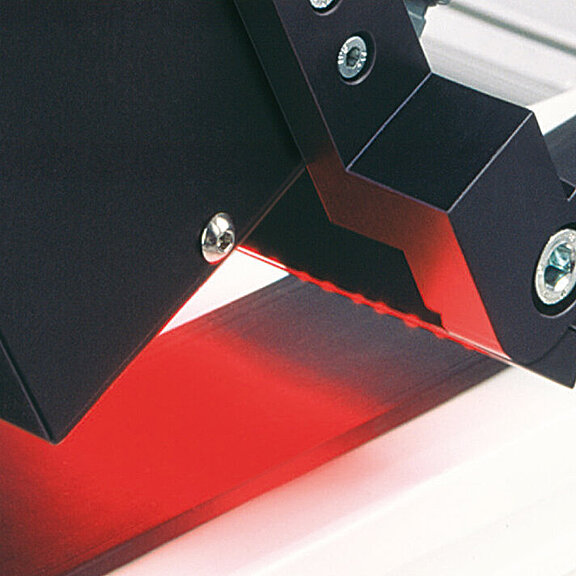

With a combined lighting and camera unit, the system measures the particle sizes in the surface of extruded test strips produced with lab-scale extruders. In this way, the system enhances process reliability as it allows to determine – ahead of production – whether a compound will be suitable for production and whether the final product will comply with the specified quality requirements.

The usually about 1-meter-long test strips produced by a lab-scale extruder are placed on the conveyor belt of the PCR system. A high-resolution camera scans the strip surface as it passes through the measuring unit. PC7 Roughness captures particles from 20 µm upwards and evaluates their size distribution. In the event that the distribution does not comply with the specifications, an alarm is triggered and digital or analog I/O signals are sent out to stop the machine.

The available data can be used in an automated and efficient process to decide on an objective basis whether the compound is suitable for further processing or not.