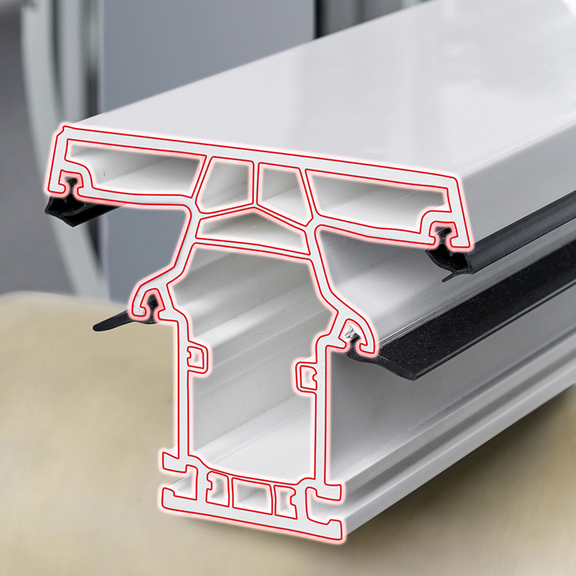

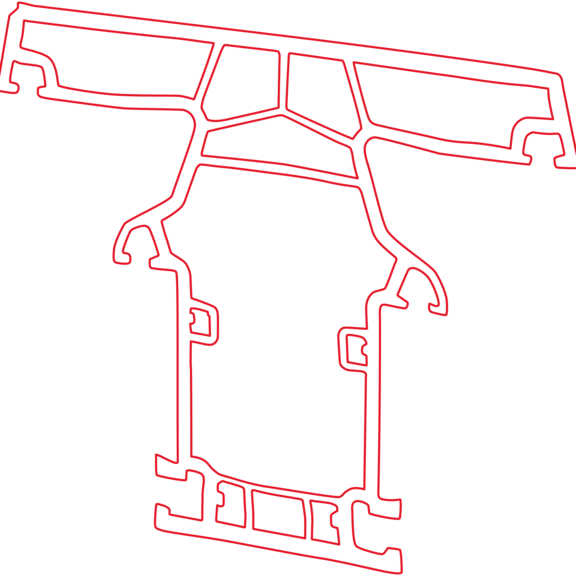

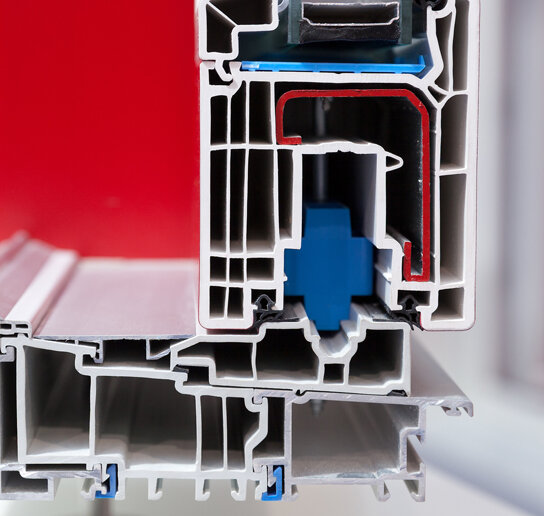

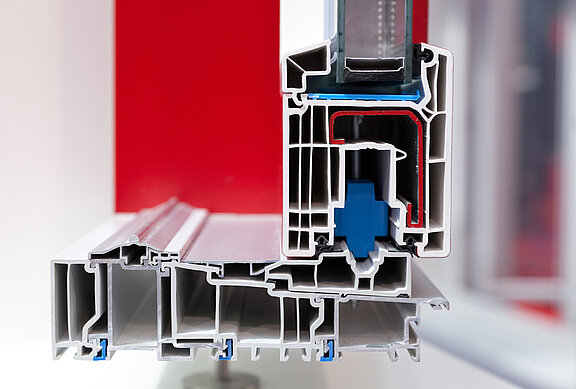

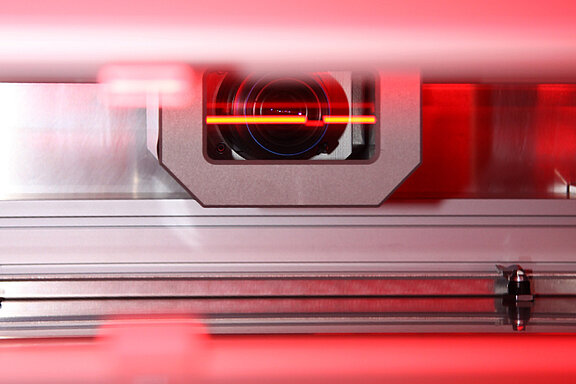

New and groundbreaking: The first ever technology to measure the inside cross-section geometry of profiles – inline and automatically!

ProfilControl 7 ICSM (Inner Cross-Segment Measurement) inspects thicknesses of walls and inside webs, contour, radii, clamping sections, coating thickness, rate of recycled material, etc. directly after the cutting device, making time-consuming manual quality control by means of projectors redundant.

Flaws occurring during production can now be detected much earlier and corrected in real time, dramatically reducing out-of-spec production. Another advantage of this innovative technology is that instead of picking random samples, PC7 ICSM checks the inner cross section of all the profiles within a batch.

And what’s more: Highly specialized algorithms measure not only the coating layers and wall thicknesses, but also the rate of recycled material used. Thus, you can increase the rate of recycled material in profile production up to the ultimate possible limit because you can rely on the rate being continuously checked by the inspection system when the profile leaves the cutter. For maximum resource saving!

Saw Control

Cuts your product to the correct length and cuts out defects with minimal waste.

With its Saw Control module, Pixargus makes cutting-to-length an integrated part of quality control in profile production.

The Saw Control software performs two basic functions. On the one hand, it sets the cutting intervals for the shear. If set at, let’s say, one meter, profiles graded as

defect-free by the quality control system will be continuously cut to this length and discharged from the conveyor belt as ready-to-pack products.

However, in the event that ProfilControl 7 has detected a flaw in the product, Saw Control instantly causes the shear to make an extra cut in real time to remove just the out-of-spec part from the profile.

This minimizes waste and saves time. Thanks to the Saw Control module, out-of spec portions of profiles can be sorted out much faster because the operators immediately recognize them as a short length comes along.