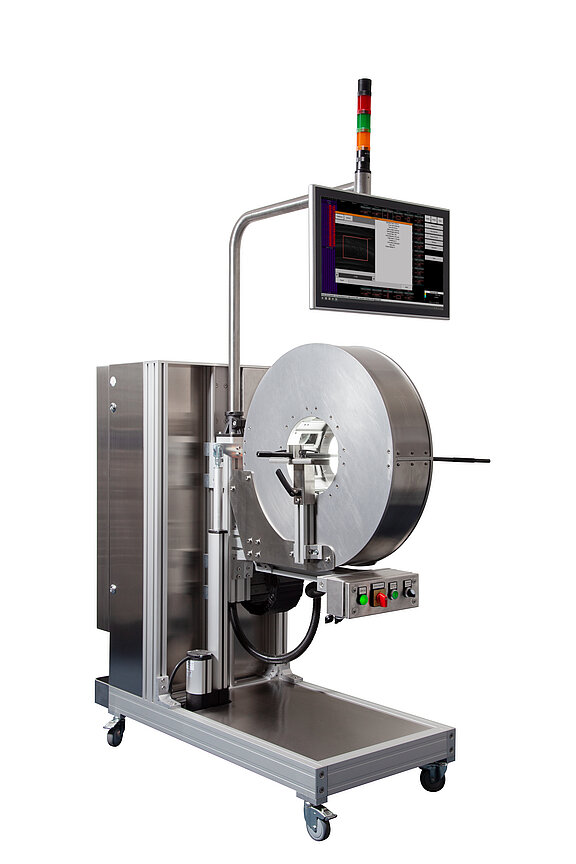

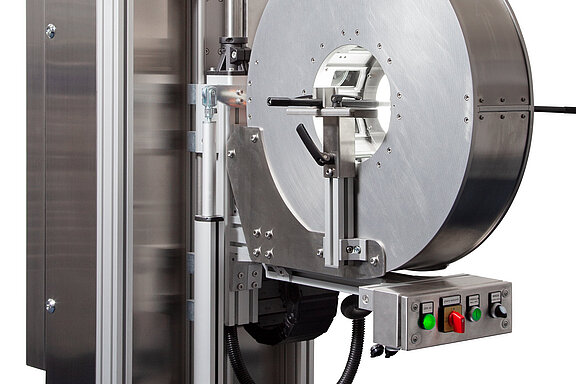

This new surface inspection system is the first ever system to master the challenging task of inline quality control of flexible tubing such as corrugated and spiral tubes.

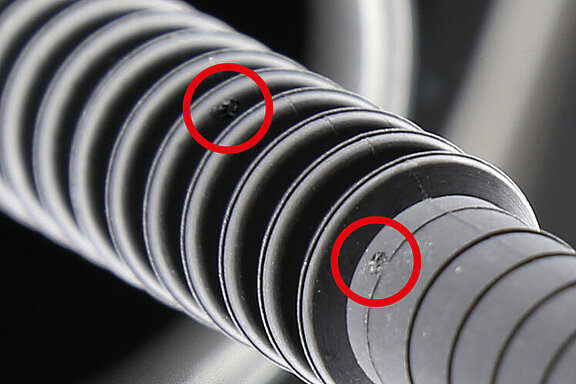

What used to be the most difficult terrain for quality inspection has now been successfully solved by PIXARGUS: PC7 Corrugated Tube inspects the entire ring structures of corrugated tubes - not only the peaks and valleys, but the complete transition areas in between - 100%!

Thanks to newly developed hardware and specially designed algorithms, this innovative system can scan the corrugated structure from both sides, enabling nspection not only of the peaks and valleys, but also of the transition areas that conventional systems are unable to capture.

PC7 Surface Corrugated Tube detects surface defects such as holes, blisters, lump defects, scratches, fissures etc. with 100%

reliability over the entire surface area of corrugated tubes. This automated inspection process is a milestone in reducing out-of-spec production of corrugated tubing and cutting production costs.

Saw Control

Cuts your product to the correct length and cuts out defects with minimal waste.

With its Saw Control module, Pixargus makes cutting-to-length an integrated part of quality control in profile production.

The Saw Control software performs two basic functions. On the one hand, it sets the cutting intervals for the shear. If set at, let’s say, one meter, profiles graded as

defect-free by the quality control system will be continuously cut to this length and discharged from the conveyor belt as ready-to-pack products.

However, in the event that ProfilControl 7 has detected a flaw in the product, Saw Control instantly causes the shear to make an extra cut in real time to remove just the out-of-spec part from the profile.

This minimizes waste and saves time. Thanks to the Saw Control module, out-of spec portions of profiles can be sorted out much faster because the operators immediately recognize them as a short length comes along.