In corrugated tube extrusion, inspection systems not only have to deal with alternating sections of corrugated and plane structures. Certain tube sections may require other inspection modes. Or, the corrugator may engrave features into the extruded product that must not be detected as defects. For this, ProfilControl 7 S CorrugatedTube now offers special algorithms that take automation in quality inspection to a new level. “It is our aim to supply systems that ideally work without any setting up to be performed by the operator,” says Jürgen Philipps, Managing Director and Head of Technological Development at PIXARGUS.

Software that adapts to different inspection tasks along corrugated tubes

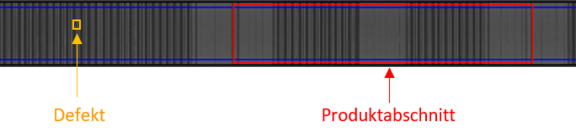

In addition to their characteristic corrugations, corrugated tubing may consist of periodically recurring sections with features that require special inspection. Automotive customers may order sets of different corrugated tubes, for example, for the assembly of engine blocks. It is possible to produce these sets of tubing in a corrugator line as a continuous product. A new algorithm of the inspection software now automatically recognizes where one of the sections within a set ends and the next one starts. If for one or several of the tube sections different inspection tasks apply, the algorithm ensures that the correct inspection parameters are used in each individual case. This makes handling faster and simpler, even in case of a highly diversified product mix.

Engraving Acceptance software distinguishes between desired and accidental markings

Corrugator dies can engrave symbols, numbers, letters and other markings into the product. To ensure that these engraved features are not detected as defects, the inspection system has to be able to recognize them as desired engravings. Also for this task, the upgrade to the ProfilControl 7 S CorrugatedTube software includes a new algorithm that automatically recognizes and accepts these engravings as desired features. This makes for additional ease of handling for the operator.

ProfilControl 7 S CorrugatedTube – 100% defect recognition in corrugated tube production

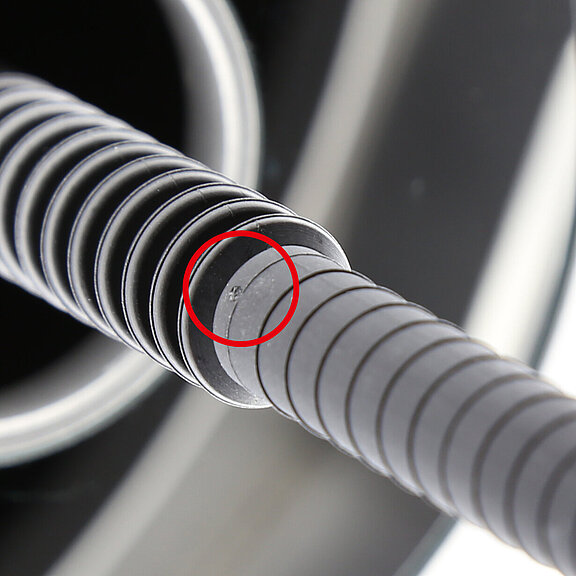

With the PIXARGUS inline inspection system ProfilControl 7 S CorrugatedTube, it has now become possible for the very first time to inspect the entire wavy structure of corrugated tubing. The innovative sensor unit is an advancement of the technology and design of PIXARGUS’ proven PC7 S Tube inspection system. Eight high-performance cameras inspect the peaks, valleys and transition areas of the corrugated structure. In doing so, they can distinguish between unwanted and desired structures and features. Holes, dents, blisters, nodes, scratches or cracks are detected with 100 percent reliability. As a result, out-of-spec production of corrugated tubing – and the production costs – can be significantly reduced.