With its turnkey inline surface inspection and dimension measuring systems, Germany-based PIXARGUS is a world leading supplier and innovation driver in automated quality control. Compact in design, the systems are in use 24/7 checking product quality in a wide range of industries, such as automotive, construction & engineering, health care products and consumer goods. Building on a reinforced local sales network, PIXARGUS is ready to further expand on the American market. At the NPE 2024 in Orlando, a key event for the global plastics industry, PIXARGUS will be spotlighting its unparalleled range of systems.

AllRounDia DualVision: The compact multi-talent for complete 360° inspection of rounds

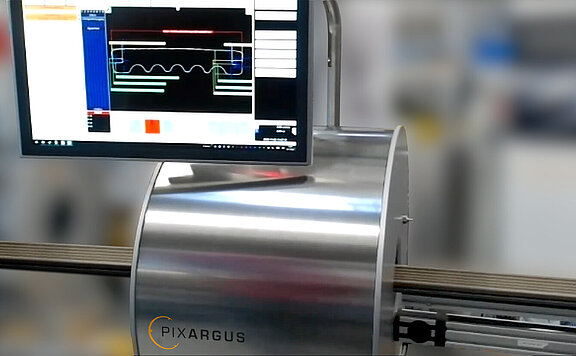

The compact two-in-one system, AllRounDia DualVision (DV), inspects both the surface and contour of tubes and hoses around their entire circumference with meticulous precision – with just one sensor unit. The PIXARGUS system employs “true” LED lighting instead of laser light as found in conventional systems. A newly developed lighting concept ensures that the field of vision and the measuring field are always perfectly lit. Thus, even difficult to detect irregularities and flaws in the material, such as cracks, inclusions, raised spots, and other high-contrast defects from a size of 0.5 mm, are reliably detected. AllRounDia DV far outshines conventional lump detection systems. The inline system inspects matte, glossy and even black surfaces of round products with ease, just as well as the surfaces of translucent and semi-transparent tubing.

The system is pre-configured for standard applications. Thus, it is ready for use virtually without any adjustment effort. Its functionality is straightforward and inspection straight to the point. The system comes with a clearly structured, intuitive HMI. It can be operated either directly with the system’s 10-inch touch screen or using a mobile tablet PC.

AllRounDia DV is currently available for round products of up to 40 mm dia. There will soon be systems for extended diameter ranges of up to 63 mm and 110 mm.

iProfilControl: Smart downsized series for the inspection of small and large profiles – also in multiple-extrusion lines

The downsized iProfilControl (iPC) series comes with proven inspection technology smartly integrated into cost-optimized entry-level systems. In these systems, PIXARGUS has adapted the capacity, range of functions and hardware to the specific inspection requirements of the process to achieve maximum efficiency with minimized equipment.

Introductory models equipped with four cameras can be scaled up to six or eight cameras for any future process requirement. Depending on what the customer wishes, the models are designed for 360° dimension measurement or 100 % surface inspection - or, as a combination of both functions, available as an All-in-One solution. Both the software and the sensor unit of the system are based on the successful ProfilControl 7 measuring technology from PIXARGUS. The iPC series comes with an impressive measurement repeatability of 0.01% of the field of vision (FOV) in comparison with competitor systems. The system indicates the smallest irregularities – even before the reject tolerance limit is reached. This allows the production process to be optimally controlled.

iProfilControl is available for FOV diameters of 90, 170 and 250 mm as standard. The 250-mm system is suitable, in particular, for large profiles, and for multiple-extrusion lines. Profiles produced in double-strand extrusion lines can be inspected with the specifically developed software capable of capturing both surface and geometrical defects around the entire circumference of the profiles. The compact iPC desk-top devices come with an integrated computing unit. They can be operated via touchscreen, tablet, notebook or PC.

ProfilControl 7 S CorrugatedTube: Reliable surface inspection in quality control of corrugated tubes

What used to be the most difficult terrain for quality inspection is no longer a problem for PIXARGUS: With ProfilControl7 Corrugated Tube it is now possible to inspect the entire surface structure of corrugated tubes – not only the peaks and valleys, but also the transition areas in between – with high precision. The specially developed, innovative measuring head features eight high-performance cameras that capture the entire surface structure typical of corrugated tubing from different angles. The inspection algorithms employed automatically recognize and differentiate between plain and corrugated tube sections, thus ensuring that defects such as holes, dents, blisters, lumps, scratches and cracks are reliably detected in all areas of the products. But the software can do even more than that: In addition to their characteristic corrugations, corrugated tubing may consist of periodically recurring sections with features that require special attention. For this purpose, the software includes a dedicated algorithm that, in addition to recognizing where such extraordinary tube sections start and end, automatically adapts the inspection parameters accordingly. This facilitates and accelerates handling at the production line, in particular in case of highly diversified product mixes.

ProfilControl 7 CorrugatedTube is designed for the inspection of up to 30-mm-diameter corrugated and spiral tubes.

ProfilControl 7 WoodPlasticComposites (WPC): Dimension measurement and surface inspection of deck boards made of wood-plastic composites

With its highly sophisticated measuring technology, the ProfilControl 7 DX WPC inline system ensures perfect shape of deck boards made of wood-plastic composites. PIXARGUS has masterly adapted its best-selling product family, ProfilControl7, to this challenging inspection task. In addition to measuring the outside profile contour, it excels in checking the quality of critical features. The 8 high-resolution cameras of the system capture radii, angles, distances, lengths, heights and widths inline, during the running process. This fully automatic inspection ensures that, e.g., the deep grooves along the edges for fixing the deck boards are of perfect shape. The system requires minimum handling - from quick commissioning and set-up of the system through to the automated switch-over from one product variant to another.

In the DualVision version, the system simultaneously performs the 360° dimension measurement and the surface inspection of the product. Typical surface defects, such as cracks, notches and edge defects, are reliably detected.

This highly compact system also supports process automation from the extruder through to automated packaging. The intelligent software of the system can also be used to have a fully automatic product grading process based on the previously acquired quality data. Boards graded as defect-free will thus be automatically stacked ready for dispatch.

ProfilControl 7 WPC can inspect up to 250-mm-wide products and is designed to cope with the harshest production environments.

With strong partners on the US market

As part of CiTEX Holding, PIXARGUS collaborates with partners who have specialist expertise in extrusion technology. CiTEX-company iNOEX, for example, are leading experts in x-ray and radar-based measuring systems for round products, with a focus on tube wall measurements. This is a perfect complement to PIXARGUS’ successful AllRounDia-DualVision technology - a camera-based system for outside surface inspection and dimension measurement of tubes and hoses that performs both measurements with just one sensor head. Through its partnership with iNOEX, PIXARGUS boasts a powerful sales network in the North-American and Asian markets.